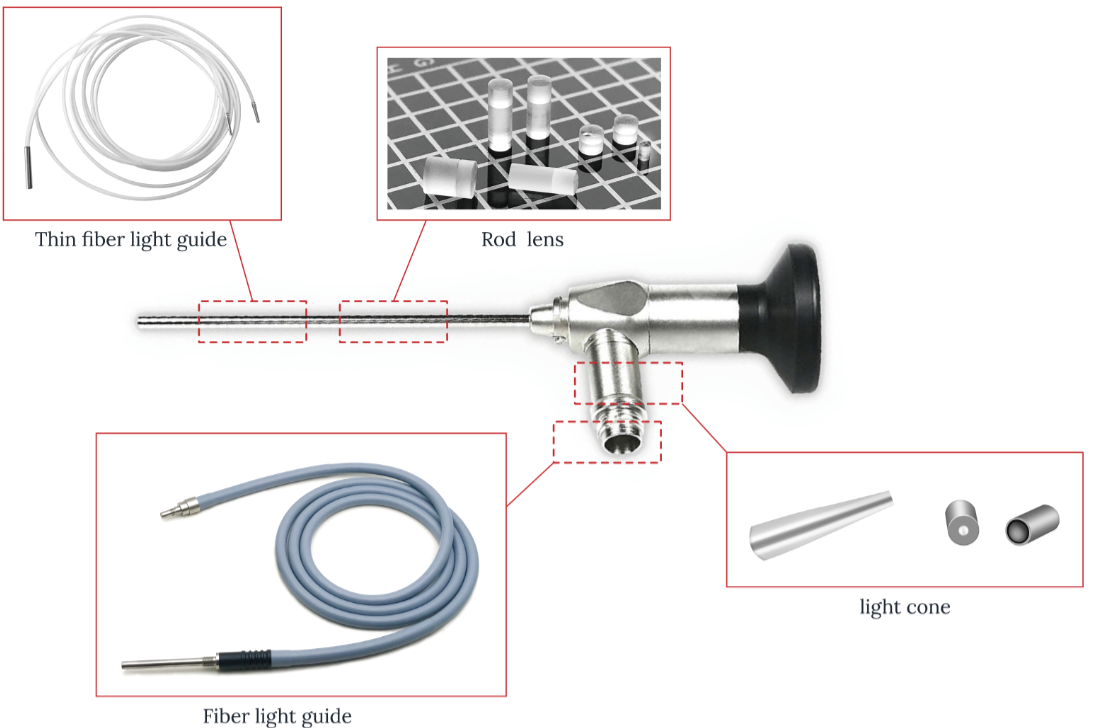

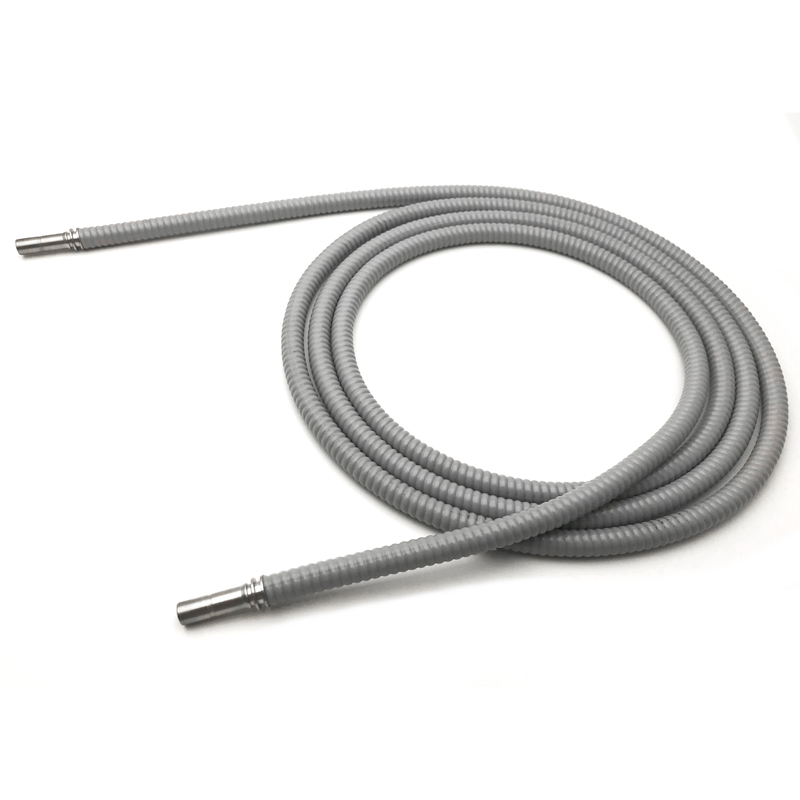

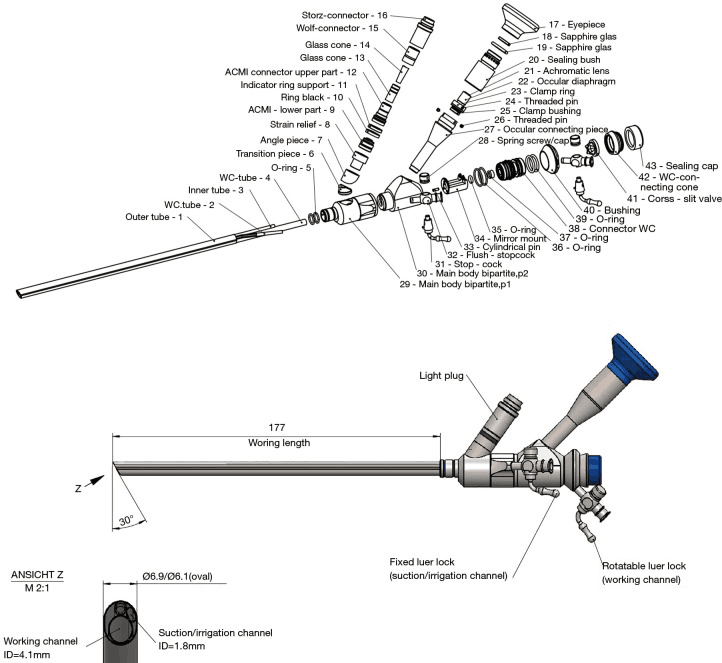

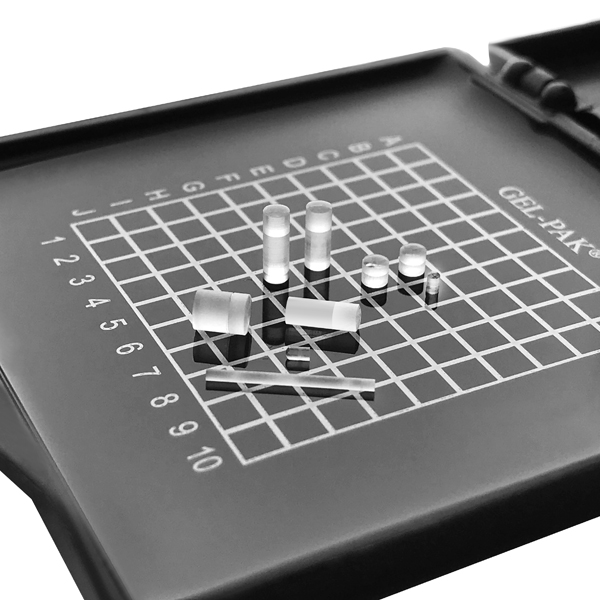

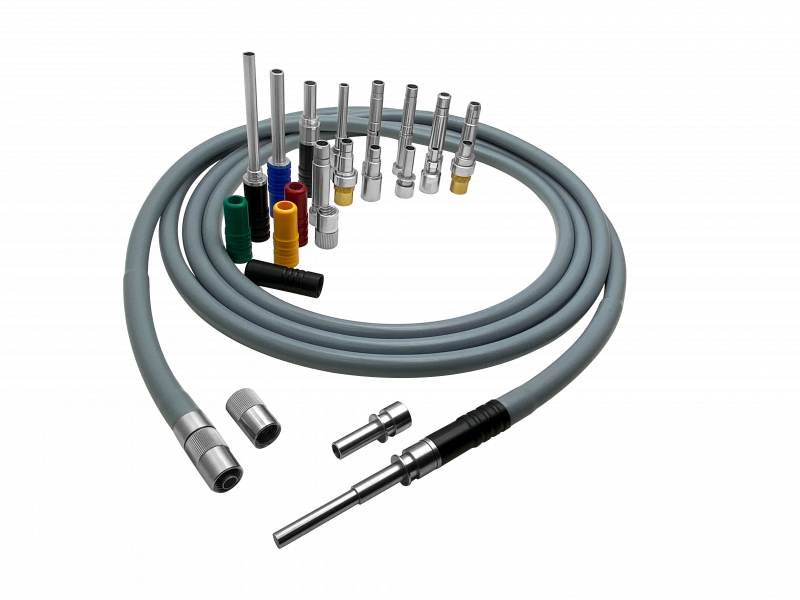

Fiber Light Cable For Rigid Endoscope

Material:Bundle Diameter:

2.5 / 3.5 / 4.8 mm or other

Cable Length:

1m ~ 5m

Sheathing:

Universal light guide: Stainless Armor + Mesh Grid + Silicone tube

Color of Sheathing: Grey, Blue

End Processing:

Bonded / Temperature Resistance 200°

Fused / Temperature Resistance 350°

Logo:

Can be customized on both end

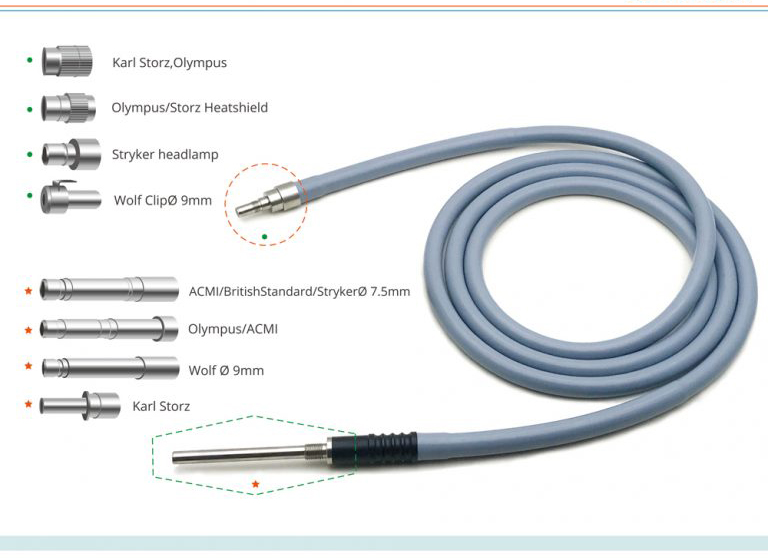

Universal Light Cables are compatible with different stainless steel connectors, allowing versatile use of the light sources for different endoscopes, and it can be selected according to the specific requirements of users. The common type of light guide cable with bonded/glued end-surface treatment of the fiber suitable for Halogen light source, temperature resistance is 200°. For the high performance with fused fiber cables provide high temperature resistance which up to 350° at the light source end.

Features:

- High Temperature Resistance and High Pressure

- High White Light Transmission with low color shift

- Stainless Steel Coil plus Nylon Mesh Grid for internal protection

- Medical Grade silicone for External protection

- Suitable for fully Autoclave, 134℃, 3bar, 10mins

- Versatility color of sheathing available

wdt_ID Fiber end treatment Bonded (Glued) Fiber Fused Fiber

1

Transmission: Cable length = 3m

CA~50%

CA~70%

39

Bundle diameter

φ1.8mm /φ2.5mm /φ3.5mm /φ4.8mm or on request

same as Bonded (Glued) Fiber Type's

40

Length of cable

1.8m / 2.5m / 3.0m / 3.5m or upon request

same as Bonded (Glued) Fiber Type's

41

Connector Compatible

Carl Storz / Olympus / Wolf/ Stryker/ ACMI / or customized

same as Bonded (Glued) Fiber Type's

43

Available Light Source

Halogen

LED , Xenon

44

Temperature Resistance

150°~200° for the Bonded/Glued Fiber end treatment

350° for the Fused Fiber end treatment

45

Minimum Bending Radius

50mm

50mm

46

Sheathing

Universal light guide: Stainless Armor + Mesh Grid + Silicone tube Color of Sheathing - Grey, Blue, White

same as Bonded (Glued) Fiber Type's

47

Sterilization method

Autoclaving 134℃, 10 min , >100 cycles

Autoclaving 134℃, 10 min , >100 cycles

The cables can be manufactured with different end-surface treatment of fiber.

1/Bonded or Glued

Bonded fiber cables are filled out with high temperature adhesives in between the spaces, temperature resistance 200°

2/Fused (on the light source end)

Fused fiber cables are made by high pressure and heat on the light source end, temperature resistance 350°. In comparison with bonded fiber cables, they have the following benefits.

-

Provide 20%~30% more light transmission on the light source end

-

Increase the ability to withstand high temperature and light intensities

-

Used with high intensity Xenon light sources

3/Extremely fused (on both end)

Extremely hot fused fiber cables are made by high pressure and heat on both end, temperature resistance 350°. In comparison with the other two, they have the following benefits.

-

Provide 20%~30% more light transmission on both end

-

Increase the ability to withstand high temperature and light intensities

-

Used with high intensity Xenon light sources

|

Fused fiber |

Bonded (glue) fiber |

Connector: The light source end and endoscope end of universal guide light cable adopts metric thread, which is compatible with general commercial connector and matches various light sources of different endoscope.

Fiber Light Cables for Rigid Endoscope