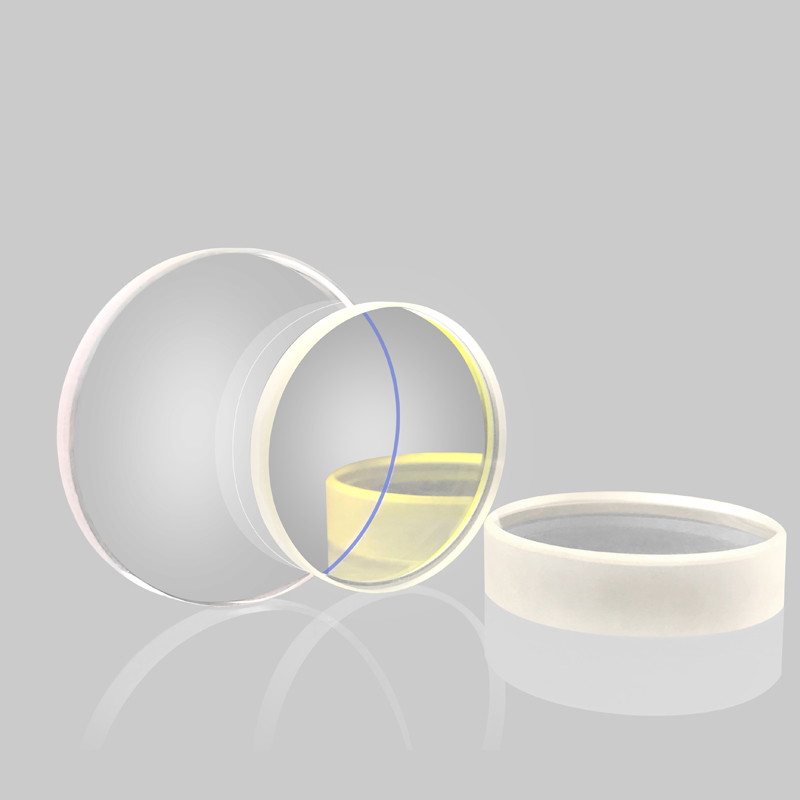

Silicon Windows / Lenses

Material:

Silicon

Thickness:

+/-0.2mm

Surface Flatness:

N<1λ

Coating:

Uncoated,

AR/AR@3-5um, Ravg<2.0%

Diameter Tolerance:

+0.0,-0.1mm

Surface Quality:

80/50~40/20

Parallelism:

<2′

Silicon and Germanium lens: for infrared measurement devices for non-contact temperature measurement, including stationary IR thermometers, and infrared cameras for point of Care Testing (POCT) devices.

Silicon Windows offers high thermal conductivity and low density, making it suitable for laser windows. However, since silicon has a strong absorption band at 9 µm, it is not suitable for use with CO2 laser transmission applications.

wdt_ID Attributes Value

1

Material

Silicon

15

Dimension Range

Diameter: 3~300mm

Thinckness:1~50mm

16

Tolerance

+/-0.01mm or customize

17

Surface Quality

80/50~40/20 or customize

18

Surface Flatness

N<1λ or customize

19

Clear Aperture

>90%

20

Parallelism

<10”

21

Chamfer

Protective <0.5mm x 45°

37

Coating

Uncoated

AR Coating

DLC coating

| wdt_ID | Attributes | Value |

|---|---|---|

| 1 | Material | Silicon |

| 15 | Dimension Range | Diameter: 3~300mm Thinckness:1~50mm |

| 16 | Tolerance | +/-0.01mm or customize |

| 17 | Surface Quality | 80/50~40/20 or customize |

| 18 | Surface Flatness | N<1λ or customize |

| 19 | Clear Aperture | >90% |

| 20 | Parallelism | <10” |

| 21 | Chamfer | Protective <0.5mm x 45° |

| 37 | Coating | Uncoated AR Coating DLC coating |

-

Dimension and shape can be customized, such as: Circular, Square, Triangle or others.

Within the range of 1.2-8um, Silicon is the most commonly used material for fabricating high infrared imaging system.

- Thermal imager

- Infrared temperature instrument

- Long pass filter (for wavelengths greater than 2 µm)

- Night sight

- Laser mirror

- Armament

- Space satellite

- High transmittance at 1.2-8 um

- Light weight, low density, high hardness, suitable for weight sensitive applications / Knoop hardness: 1100 kg / mm2, density: 5.27 g / cm3

- High refractive index (3.4 at 3-5um)

wdt_ID Part No. Material S/D dia (mm) Thickness Coating

27

WIN5101

Silicon

60/40

10.0

1.0

None

90

WIN51252

Silicon

60/40

12.5

2.0

None

91

WIN51272

Silicon

60/40

12.7

2.0

None

92

WIN5252

Silicon

60/40

25.0

2.0

None

93

WIN52542

Silicon

60/40

25.4

2.0

None

94

WIN5402

Silicon

60/40

40.0

2.0

None

135

WIN5503

Silicon

60/40

50.0

3.0

None

136

WIN51011

Silicon

60/40

10.0

1.0

AR/AR@3-5um, Ravg<2.0%

137

WIN512521

Silicon

60/40

12.5

2.0

AR/AR@3-5um, Ravg<2.0%

138

WIN512721

Silicon

60/40

12.7

2.0

AR/AR@3-5um, Ravg<2.0%

139

WIN52521

Silicon

60/40

25.0

2.0

AR/AR@3-5um, Ravg<2.0%

140

WIN525421

Silicon

60/40

25.4

2.0

AR/AR@3-5um, Ravg<2.0%

141

WIN54021

Silicon

60/40

40.0

2.0

AR/AR@3-5um, Ravg<2.0%

142

WIN55031

Silicon

60/40

50.0

3.0

AR/AR@3-5um, Ravg<2.0%

| wdt_ID | Part No. | Material | S/D | dia (mm) | Thickness | Coating |

|---|---|---|---|---|---|---|

| 27 | WIN5101 | Silicon | 60/40 | 10.0 | 1.0 | None |

| 90 | WIN51252 | Silicon | 60/40 | 12.5 | 2.0 | None |

| 91 | WIN51272 | Silicon | 60/40 | 12.7 | 2.0 | None |

| 92 | WIN5252 | Silicon | 60/40 | 25.0 | 2.0 | None |

| 93 | WIN52542 | Silicon | 60/40 | 25.4 | 2.0 | None |

| 94 | WIN5402 | Silicon | 60/40 | 40.0 | 2.0 | None |

| 135 | WIN5503 | Silicon | 60/40 | 50.0 | 3.0 | None |

| 136 | WIN51011 | Silicon | 60/40 | 10.0 | 1.0 | AR/AR@3-5um, Ravg<2.0% |

| 137 | WIN512521 | Silicon | 60/40 | 12.5 | 2.0 | AR/AR@3-5um, Ravg<2.0% |

| 138 | WIN512721 | Silicon | 60/40 | 12.7 | 2.0 | AR/AR@3-5um, Ravg<2.0% |

| 139 | WIN52521 | Silicon | 60/40 | 25.0 | 2.0 | AR/AR@3-5um, Ravg<2.0% |

| 140 | WIN525421 | Silicon | 60/40 | 25.4 | 2.0 | AR/AR@3-5um, Ravg<2.0% |

| 141 | WIN54021 | Silicon | 60/40 | 40.0 | 2.0 | AR/AR@3-5um, Ravg<2.0% |

| 142 | WIN55031 | Silicon | 60/40 | 50.0 | 3.0 | AR/AR@3-5um, Ravg<2.0% |