CNC generation Spherical Surface

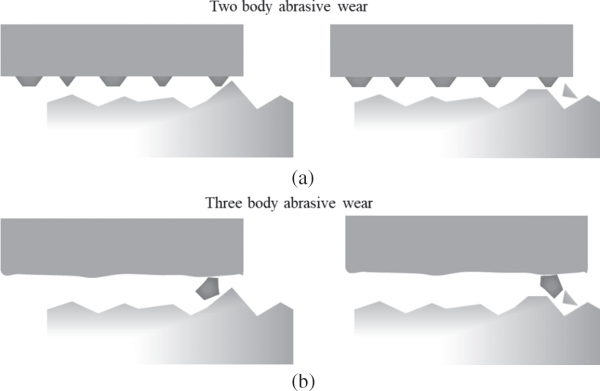

Computer numerically controlled (CNC) generation was enabled by computers and relies heavily on bound abrasive tools. A bound or fixed abrasive tool typically consists of a metal or resin matrix with diamonds or other abrasives dispersed within the matrix. One of the major differences between bound abrasive CNC generation and loose abrasive lapping is the wear mechanism. Loose abrasive lapping consists of three body abrasive wear and bound abrasive lapping is two body abrasion. Figure below illustrates the three- versus two-body abrasion. Two-body abrasion is not exclusive to CNC generation; it can also exist in non-CNC applications such as diamond pellet grinding. Similarly, CNC equipment can also utilize three-body abrasive wear.

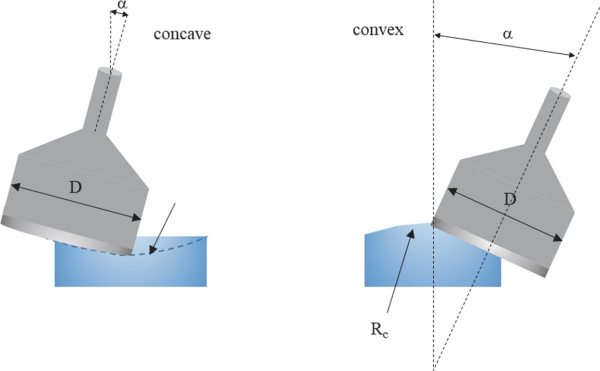

Conventional grinding processes require dedicated tooling for every unique radius and diameter. Bound abrasive ring tools for CNC generation significantly reduce the number of tools necessary. Multiple radii can be generated with one bound abrasive ring tool by adjusting the head angle. Ring tools can be used to generate flat, spherical, concave or convex surfaces using

where a is the wheel angle, D is the wheel diameter and Rc is the desired radius of curvature. Schematic drawings of both concave and convex configurations are shown in Figure below

Additional work has been done by several to reduce machine vibration, increase stability and advance computer programming for CNC generation. The goal is to increase the complexity of geometries available as well as the level of resulting precision of the generated surfaces. The introduction of ultrasonic vibration-assistance to the generation process enabled faster material removal rates with less tool wear. This results in more predicable surface form and surface texture. Experimental results showed that material removal rates were three times higher with ultrasonic-assistance on than when it was off. Further testing showed that the amount of residual damage was similar between the two methods . As mentioned earlier, the amount of damage induced in each generation step creates potential subsurface damage in subsequent grinding and polishing steps.