Concerns of Laser Safety

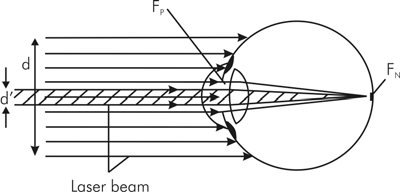

Regarding their hazard potential, lasers are categorized according to safety class 1 through 4. High-power lasers, which are the only ones used for materials processing (> 0.5 W in the CW mode), are invariably class 4 lasers, therefore requiring the strictest safety protection. But even high-power lasers show major differences with regard to the potential hazard primarily because of the wavelength and its effect on the human eye. The human lens and cornea focus collimated (i.e., parallel) laser radiation onto a tiny spot on the retina that is only a few percent of a millimeter in size –thus amplifying the intensity by a factor of approx. 300,000, a phenomenon known as the m “burning-glass effect” that can easily damage the retina.

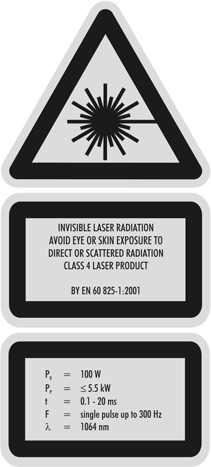

This, however, is only valid of visible radiation as well as the near ultraviolet and the near infrared region. CO2 laser radiation, with a wavelength of 10.6 µm in the midinfrared range, is completely absorbed by the outer corneal layer, eliminating the burning-glass effect. The main hazard in this case is corneal burning. On the other hand, totally different arguments apply to the Nd:YAG laser. 40 % of its radiation, at a wavelength of 1.06 µm, reach the retina and may severely damage the eye by retinal burns, but also cataract. Especially with diode lasers that emit at wavelengths of 0.8 to 1 µm, adequate eye protection is a priority with all safety instructions, since the radiation almost fully meets the retina. The laser safety standard IEC 60825-1, which lists pertinent limiting values for the maximum permissible exposure (MPE) for various wavelengths and operating modes, is world-wide accepted. In the European community it is mandatory. In some countries, further national regulations have to be observed. In the USA the use of laser products is governed by the regulation 21 CFR 1040.10 and the “Laser Notice 50”, issued in 2001 by the CDRH which is part of the FDA (food and drug administration). These exposure limits must be enforced outside the laser controlled area so as to protect third parties. Inside the shielded laser controlled area, on the other hand, these limiting values may be exceeded under strictly monitored conditions. The supervision by a trained laser safety officer (LSO) is particularly important and specified in the guidelines. Additionally, all personnel have to wear laser safety goggles and there are additional technical and organizational measures to be implemented (warning lamp, key switch, appropriate signs, safety instructions, etc.). In some countries another provision stipulates that the factory inspectorate division in charge and the employers’ liability insurance association must be informed of the use of class 4 lasers on the company’s premises.

Class 4 lasers represent a potential hazard not only with a direct beam, but also by reflections on plain metal surfaces or diffuse scattered radiation on rough surfaces. Since laser radiation, especially in the infrared range, is invisible, beam delivery through metal tubes or along optical fibers is advised. When measurements or maintenance tasks are to be carried out that can only be performed on the open beam, it is vitally necessary to indicate the beam – at least temporarily – with auxiliary lines. Additionally, the laser area should be limited by a beam stop and its immediate environment should be fenced off. Apart from laser radiation, persons may also be endangered by fire, secondary radiation, and harmful substances created by laser materials processing (such as particulate fume, or toxic materials). The manufacturer must identify the laser with the standard laser warning sign. Further labels are required indicating the laser class, the wavelength, the maximum output power and possibly the pulse frequency. Manufacturing plants generally require a class 1 system that does not endanger the user in any way as long as the housing remains closed. The processing area, too, must be appropriately shielded. This is not usually a problem with two-dimensional applications. For radiation with a variable direction, on the other hand, such as robot systems or multi-axes installations, closed cabins with suitable protective walls are necessary. In this context the ICE 60825-4 standard differentiates between passive and active laser guards. Active ones are equipped with a built-in sensor system automatically shutting off the laser in case of an inadmissible radiation increase. Fiber-coupled processing optics must be protected against fiber fracture; this is usually achieved with a built-in interlock system.

Laser safety goggles are selected in accordance with the relevant wavelength, the operating mode (continuous wave, pulsed, etc.) and the power density (intensity) of the collimated laser beam. The protection time must be at least 10 seconds; and it is not normally longer than that during exposure to irradiation with the specified maximum power! Protective goggles do not usually protect the eye from a focused beam at all. When lasers with a different wavelength are operated in the same room, combination laser safety goggles should be used. Persons with ametropia may wish to buy laser safety goggles with correction lenses, but they should see an ophthalmologist first. Basically, all protective goggles should be in perfect condition and should be equipped with a DIN mark. Fortunately, accidents involving laser manufacturing plants are rare indeed. However, if such an accident is suspected (for instance due to intense blinding, luminous effects) or visual field defects, immediate medical attention is required (ophthalmic fluorescence angiography), since the damage, due to the commencement of cicatrization of the tissue within a few days, can no longer be attributed to laser radiation with any certainty at all.