Laser in Industrial Applications

Laser-based techniques have the following decisive advantages over conventional processing methods:

- Excellent beam control and easy conversion to automatic operation

- Non-contact, zero-force processing

- No tool wear

- Low thermal input on the workpiece, due to the very high energy density at the processing point, which is concentrated in a tiny spot

- High processing speed combined with excellent reproducibility of the processing results

- Allows the processing of very hard, brittle, or soft materials

- In combination with a suitable system technology, any desired contour may be processed

- Realization of a variety of different machining geometries without changing tools

- Reduced dead cycle times due to beam activation and deactivation without delay

- Excellent versatility with regard to various manufacturing techniques

- Easy integration into conventional manufacturing processes

Any of these aspects may argue strongly in favor of using lasers for manufacturing purposes. In the end, however, investment decisions are based on actual technological and economical benefits associated with individual applications.

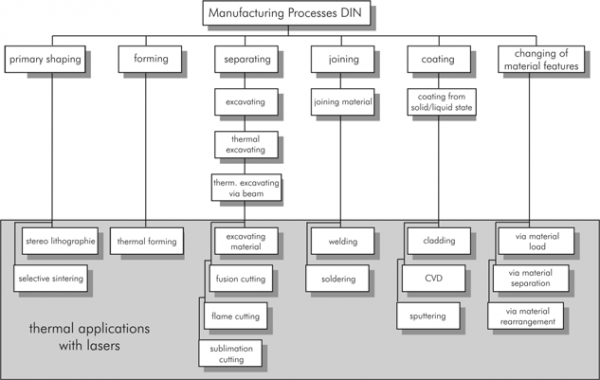

The various manufacturing processes possible with solid-state, CO2 and diode lasers can be classified under the production methods according to DIN standards.

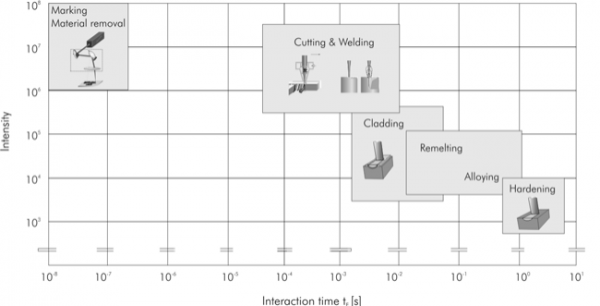

In conjunction with metal processing, the values shown in the following figure (Figure below) represent commonly used interaction times and laser beam intensities.

Separation techniques require high intensities combined with short interaction times of the laser beam with the material. Slightly longer interaction times are required for joining purposes. Relatively low intensities and long interaction times are required in conjunction with processes where a comparatively large material volume is to be heated without risking material evaporation. In lasers featuring continuous operation, variation of intensity may be effected by adjusting the power or by focusing the laser beam; interaction times are tuned by the speed of the workpiece. Pulsable

lasers, by variation of the power, duration, energy, frequency, and pulse shaping, offer additional possibilities of tailoring a given material processing method to specific requirements depending on the material and the workpiece.