Basic principles of laser physics

The term LASER is an acronym for “light amplification by stimulated emission of radiation”. Laser radiation, in simple terms, is light – more specifically, it is an electromagnetic wave generated by a laser-active medium. In industrial laser technology, CO2 gas and the element neodymium (Nd), in particular, are of primary importance as laser-active materials.

By using suitable technologies, energy is transferred to the laser-active material, thus raising the energy level of the medium; a process that is referred to as pumping.

Basically, all atoms, molecules, etc. strive to attain their lowest energy level. Laser active materials that are forcefully pumped to higher energy levels have a definite advantage over non-laser-active materials. Their high-energy states are more longlived than physically expected (meta-stable condition). This principle is utilized in a laser beam source, which generates more stimulated ions or molecules than ground state ones (inversion of the occupation numbers – population inversion).

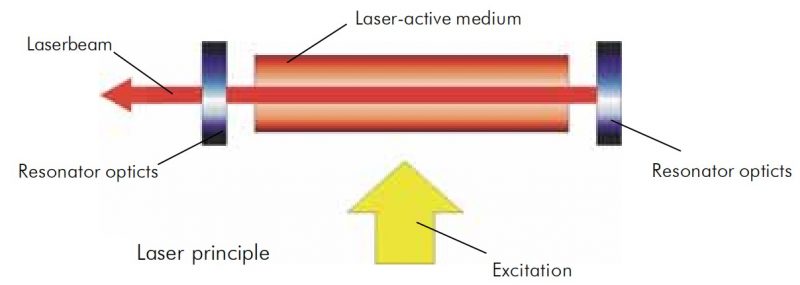

If one of the “high-energy” particles returns to a lower energy level by chance (spontaneous emission), then the energy difference between these two levels is released as a light quantum (photon). If the laser instrument is constructed accordingly, this photon may then be re-reflected onto the laser-active medium by appropriate mirrors, resulting in amplification by stimulation. This single photon, in accordance with Albert Einstein’s postulate (1917), stimulates another high-energy particle in the laser-active medium to return to the lower energy level (stimulated emission). Simultaneously, a second photon with the same energy as the first one (monochromatic), which is vibrating in the same phase (coherent) and along the

same optical axis, is emitted.

Depending on the amplification, which is a material-specific parameter of the laser-active medium, photons which are exact copies of the very first photon, in terms of these three parameters, are now generated between the two mirrors forming the resonator and creating a regular cascade. After time, this process levels off and reaches an equilibrium of energy supplied and dissipated.

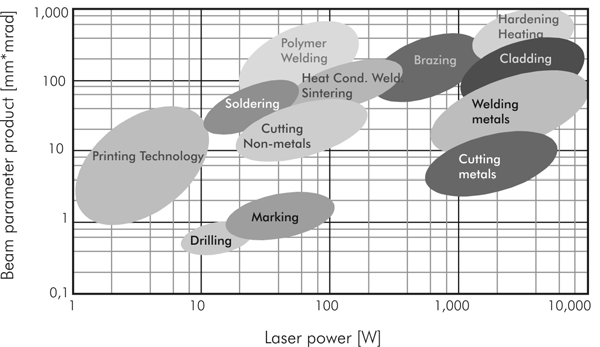

A certain share of the radiation reflected back and forth between the two mirrors is obtained from the resonator with the appropriate optical systems and is, as a working beam, directed onto the workpiece. Depending on the type of beam guiding system and subsequent focusing, combined with the effective output, the laser may be used for cutting, welding, hardening, soldering, engraving, etc.

In CO2 lasers, energy supply and subsequent events proceed in a mixture of helium, nitrogen, and CO2 gas. Energy is supplied to the laser-active CO2 gas by electrical gas discharge (direct current or radio frequency). Today’s CO2 lasers attain output powers of up to 20,000 watts at a radiation wavelength of 10.6 µm.

Lasers with neodymium as an active material commonly utilize a solid-state crystal of yttrium-aluminum garnet (YAG) enveloping the neodymium (Nd:YAG laser). Energy is supplied by exposure to intense light radiation generated by flashlamps, arc lamps or by laser diodes. The output power may reach up to 8,000 watts at a wavelength of 1.064 µm.

Diode lasers, which are gaining increasing importance throughout industry, have an essentially different functional principle. In a semiconductor component, laser light may be produced by recombination of electrons and so-called holes. Such a single emitter has a power of approx. 5-50 mW. The most popular application example for such a single emitter is within a CD player. In modern industrial diode lasers, many thousands of these single beam sources are optically and electrically combined to afford powers of up to 3,100 watts. These are utilized, for instance, for welding, surface treatment or soldering. The respective wavelength, depending on the construction of the semiconductor, may equal 808 nm, 940 nm, or 980 nm; or it may be a superposition of several of these wavelengths.

Another type of laser that has conquered its place in industrial laser machining, is the excimer laser. The term “excimer” is derived from excited dimer, a name for reactive inert gases. The active material of this laser consists of inert gas halogenides (argon, krypton/fluorine) that are stimulated by a pulsed direct current. In this case, laser wavelengths – by contrast to the above-mentioned laser sources – are in the ultra-violet spectral range (e.g. 248 nm for a krypton-fluoride laser). This, among others, allows special applications, e.g. in conjunction with drilling and ablation. In

addition, excimer lasers are characterized by a very brief pulse duration associated with high pulse energy. In combination with the short wavelength, these devices are particularly suitable for plastics and ceramics processing.

Beam quality, beam propagation and focusing

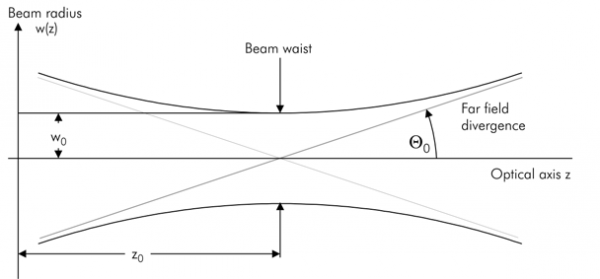

Any rotational symmetrical laser beam may be characterized by the following three parameters:

- Beam waist position z0,

- Radius of the beam waist w0,

- Far-field divergence angle Θ0.

Numbers characterizing the beam quality

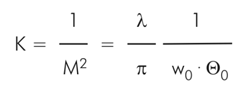

Various characteristic numbers are used to describe the beam quality of a laser beam: K, M² as well as the beam parameter product (BPP). These characteristic numbers are directly converted into each other by simple calculations.

The beam parameter product is derived from the above-mentioned parameters used to describe rotation-symmetrical laser beams. The beam parameter product is the product of the w0 and Θ0 values, and remains constant over the entire laser beam region. Changing the diameter; for instance by installing lenses and/or telescopes, will always influence the divergence. Thus, the beam parameter product is a measure of focusability. Only the use of optical systems with aberration or aperture effects may influence the beam parameter product along the external optical path.

The K resp. M2 values are a standardized measure of the beam parameter product and pertain to the physical limits of a laser beam and it’s focusability.

Both characteristic numbers are commonly used to characterize lasers whose beam quality is close to ideal; i.e., with K values in the range of 0.1 to 1 resp. M² values between 1 and 10.

The beam parameter product (w0 x Θ0) is frequently utilized instead of K and M² to characterize lasers whose beam quality is relatively far from the ideal; i.e., with K values considerably below 0.1 resp. M² larger than 10. The three mentioned characteristic numbers may be used to characterize all lasers with rotation symmetrical laser beams.

Focusing of laser beams

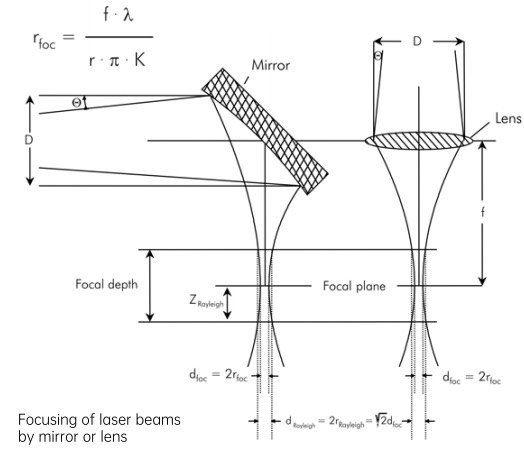

Any laser beam may be focused; i.e., it may be reduced to a tiny beam diameter by using appropriate optical elements, such as curved mirrors or lenses with a focal distance f. The focusing radius, rfoc, of a rotation symmetrical laser beam with a wavelength λ may be calculated according to the following equation, as long as the radius r of the laser beam on the mirror resp. on the lens, the far-field angle of divergence Θ0, and the beam characteristic number K are known.

The above equation shows that an ideal laser beam (K = 1/M2 = 1) with an ideal optical element at a focal distance f may be focused on a very tiny spot radius:

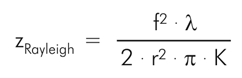

The Rayleigh length distance is the distance from the focus at which the crosssectional area of the laser beam has doubled. The depth of focus, by definition, is twice as long as the Rayleigh distance. This is quantified as follows:

At least 7 parameters are needed to describe non-rotation symmetrical laser beams; three extra characteristic values must be added for astigmatic laser beams. For instance, excimer or diode lasers considerably complicates the correct description of these lasers types. Details, however, are found in the ISO/CD 11 146 text.