Measuring Transmittance of Optical Materials

Besides the refractive index and its dependence on the wavelength, the internal transmittance of optical glass is probably the second most important property. The transmittance of an optical glass is inversely proportional to its spectral absorption. The absorption bands of a glass are closely related to its dispersion behavior. The dispersion is a measure of the change of the refractive index with wavelength.

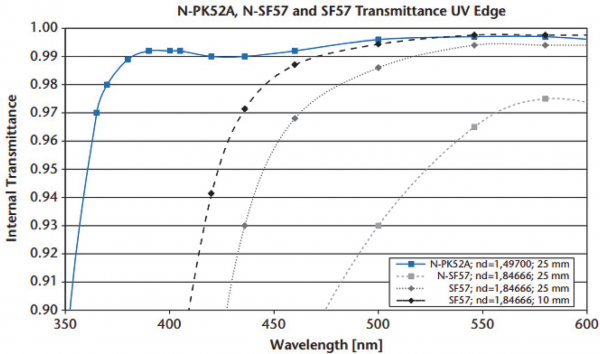

The UV transmittance characteristic (see Figure below) is mostly influenced by heavier elements in the glass composition (e.g., lead, barium, niobium, titanium, lanthanum), melting technology and/or residual impurities. These heavier elements are necessary to achieve a high refractive index but decrease the transmittance in the blue region. Therefore, high-refractive-index glasses in bigger thicknesses often show a yellowish color. Nevertheless, there are differences in the characteristic of the UV transmittance edge, depending on which heavy elements are used in the glass composition. For example, SF glasses containing lead exhibit a better transmittance in the blue spectral region compared to N-SF glass types where lead was substituted by titanium or niobium. The melting process also influences the transmittance characteristics of a glass, for example, platinum parts in the melting tank could be the source for platinum impurities in the glass, leading to a weaker UV transmittance.

Modern melting techniques aiming for the reduction of platinum contact with the melt therefore lead to better transmittance characteristics.

One way to describe the blue edge of the transmittance curve is to use the color code. The color code is a description of the position and slope of the UV transmittance edge. It lists the wavelength l80 and l5, at which the transmittance (including reflection losses) is 0.8 and 0.05 at 10-mm thickness.

The values are rounded to 10 nm and are noted by eliminating the first digit.

Color code 33/30 means for example, l80 = 330 nm and l5 = 300 nm. For high-index glass types with nd > 1.83, the data of the color codes refer to the transmittance values 0.70 and 0.05 (l70 and l5) because of the high reflection loss of this glass.

Electromagnetic radiation influences the transmittance of a glass depending on glass type and the wavelength of radiation. The influence of visible and UV radiation on glass is called solarization. The UV radiation generates color centers in the glass, leading to a reduced transmittance. The solarization behavior of optical glass can be investigated by irradiation with a xenon or mercury lamp, or with UV lasers typically below 380 nm. Glasses with low UV transmittance, e.g., with a high lead content (F and SF types), normally have small solarization effects. Several crown glasses with a higher ultraviolet transmittance change their UV-transmittance edge: PSK, BK, K,ZK, BAK, SK and LaK. The steepness of the transmittance edge becomes smaller. This effect can be reversed at higher temperatures (the higher the temperature is, the faster the effect will be reversed).

The transmittance of optical glasses is in general high in the visible and at wavelengths up to 1970 nm. The infrared transmittance is influenced by the OH content in the glass. The first small absorption can usually be found at 1450 nm. The main OH absorption band is sensitive to the atomic surrounding and typically occurs between 2.9 mm and 4.2 mm.

The short-wave infrared (SWIR) spectral band is located between the visible and the thermal infrared. Based on the existing data, all SCHOTT optical glasses can be used in the 0.9 to 1.7-mm SWIR spectral range.

Regarding a definition of the SWIR range up to 3 to 4 mm, most of the optical glasses have a low transmittance above 2 mm. Nevertheless, fluorophosphate optical glasses offer excellent transmittance even up to 4 mm [15].

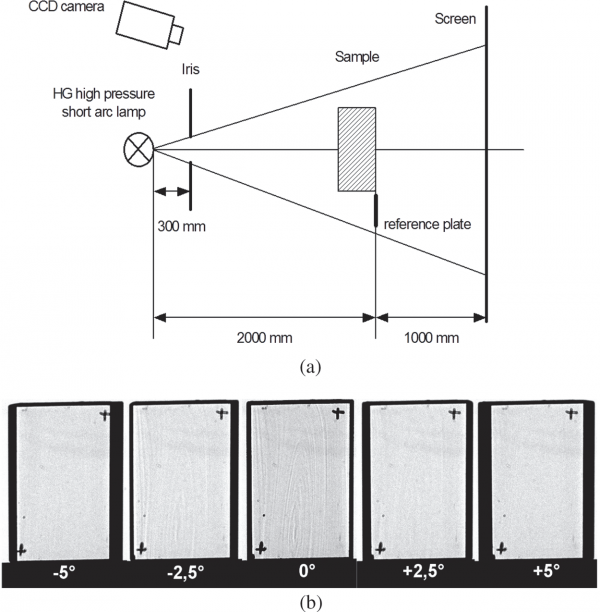

The transmittance of optical glass is measured using double-beam spectral photometers. Typical standard setups enable measurements within a wavelength region from 250 nm up to 2500 nm. The measurement accuracy over the complete spectrum is about ±0.5%. Within 400 nm to 700 nm, the accuracy is ±0.3%. The wavelength can be measured with an accuracy of ±0.2 nm and ±0.8 nm. Standard measurement sample thickness is 25 mm (20 mm x 15 mm x 25 mm). With different setups, it is possible to increase the transmittance measurement accuracy in the UV and visible range (200–850 nm) to ±0.08% and in the near-infrared range (850–2500 nm) to ±0.3% (with ±0.02 nm in the UV/VIS and ±0.08 nm in the NIR). Additionally, it is possible to expand the wavelength range from 2500 nm to 16600 nm. Within this range, the measurement accuracy is ±1%.