What is optical adhesives?

This article mainly introduces the application of optical adhesive, and the optical factors and environmental factors to be considered in the application.

Application of Optical Adhesives

Adhesives (bonds or cements) are used in optics for two main purposes:

- To bond optical elements to their housing, and

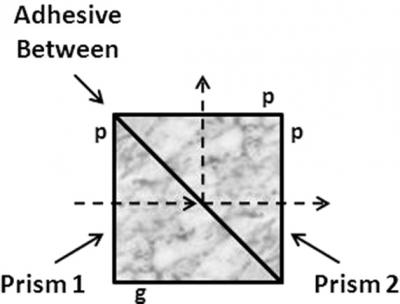

- To bond optical elements to each other, including lens to lens (for doublets or triplets) and prism to prism (for beamsplitters).

When determining how to join the optical elements, the right consideration must be taken when drawing the element to be cemented and then choosing the right adhesive to achieve the best results.

These considerations are made by the optical designer while designing the optical elements to be bonded.

(Bonding optical elements to their housing should be performed according to relevant written procedures that also include instructions for inspection and tests to verify the conformity of the bonding results to the written requirements. Those requirements are established by the designer and are not a part of this guide.)

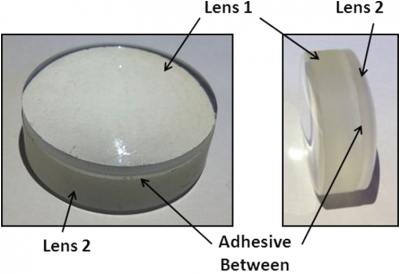

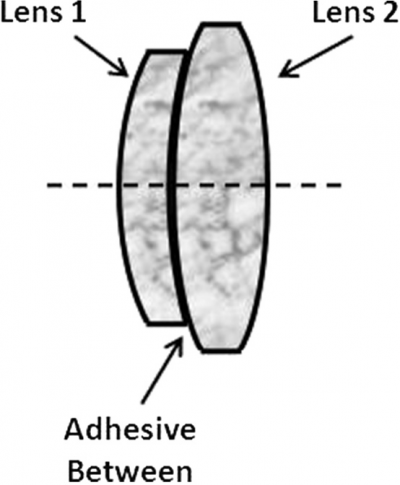

UV-curing adhesives (Figures below) are one-component materials that are cured upon exposure to UV light. These UV adhesives dominate the market for bonding optical elements due to their ease of use and fast cure time. This chapter refers basically to UV materials. Most of the following descriptions apply to other optical adhesives (two component cements), as well.

Optical considerations

- Refractive indices of the elements.

- Transmission of the elements.

- Tolerance of internal reflection and absorption.

Environmental considerations

- Working temperature extremes.

- Mechanical shock requirements.

- Chemical resistance requirements.

- Pre-bonding chemical and substance exposure.

Verifying the conformity of the adhesion of an optical bonded element (doublet, triplet, cemented prism, etc.) can include, according to the requirements, a witness sample (two bonded flat windows of the same material and of the same adhesive lot) or an actual bonded element. The test may include temperature (high and low), humidity, vibration, mechanical or thermal shock, transmission, and visual inspection with the help of proper lightning. Any change in the previous condition of the adhesive may led to item or lot rejection.

Bond Failures

When bond failure occurs, it is more likely an incorrect choice of cement type, an anomaly in the substrate preparation, or incorrect interpretation of the manufacturer’s instructions than a question of the quality of the cement.

Expired cement or inappropriate storage conditions (stored in lighted place, not in the original container or not refrigerated) will probably lead to bond failure. Failure may also occur due to incorrect requirements from the designer. In such a case, if the producer identifies the designers’ mistake, it is obligatory to inform the designer or the customer about it.

Shrinkage: All adhesives shrink upon cure. UV-cured adhesives can reduce as low as 0.2%. Low shrinkage is necessary to minimize stress and provide longterm stability. In a doublet lens, when a convex surface is bonded to a concave one, the shrinkage on the sides pulls outward. Thin elements (meniscus lenses or double concave lenses) can be exceptionally prone to distortion. Shrinkage can occur on a witness sample or on the actual element.

Decentering: In lenses (doublets, e.g., Fig. below, or triplets), an element can shift off the optical or/and mechanical axis during or after pre-cure.

This occurs faster at room temperature for two-component cements or when high temperature-oven-cure adhesives are used. The UV cements can suffer from decentering during the bonding process, too, due to a lack of a centering procedure.

Uncured lenses, elongated cure times: Cured or uncured cement can occur with all cements, as well as with UV curing, which is common in bonding optical elements. The common UV curing cements are sensitive to temperatures, transmission of substrate, wavelength, the intensity of the light source, and the distance of light source to substrate.

Haze, fog, or discoloration: Discoloration or haze that occurs during or immediately after curing is almost always a sign of contamination of the cement. For UV cements, the main reason may be uncleaned bonded surfaces.

Polishing compounds or fingerprints, if not cleaned immediately, can leave a very stubborn film and create haze, fog, or discoloration.

Cement wedge: A wedge occurs in lenses (doublets or triplets) if the bonded elements are poorly centered. In prism beamsplitters, e.g., Fig.below, incorrect measurements of the bonded element may also lead to wedging.

A cement wedge decenters the bonded lenses.

Signs of separation between the adhesive and the bonded surface:

Separation may occur due to poor surface cleaning (insufficient or inappropriate cleaning material or process).

Inclusions: Foreign particles in the cement occur mostly when the bonding area is not kept clean.

Bubbles: Bubbles are gases or air trapped in the cement. Bubbles may occur due to incomplete mixing of the two adhesive components or due to poor preparation of the bonding process.

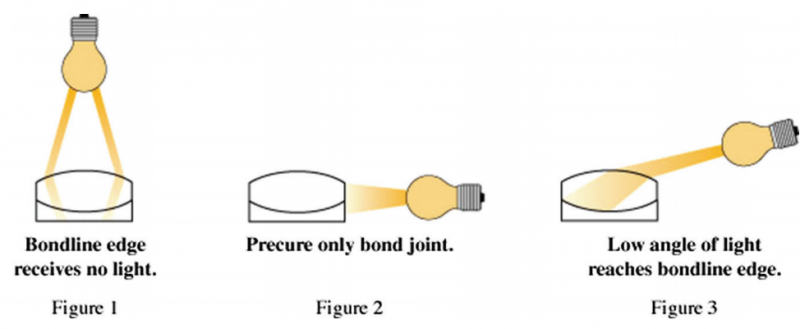

Figure below illustrates three cases of curing with UV light. In the first image, the bonding edge receives no light, the edge is not cured at the same time as the rest of the lens, and it will have internal stress that will lead to cohesive failure. Images 2 and 3 illustrate how to prevent such stresses by pre-curing only the bond joints or by illuminating the UV light at a low angle.

The last image depicts properly assembled doublets.