Bubble and inclusion measurement in Optical Material

Optical glass in general is nearly free of bubbles and inclusions compared to other technical glasses due to sophisticated production processes, which are optimized for low bubble content. Nevertheless, to specify an optical glass for a desired optical component, it is helpful to know the background on the generation of bubbles and inclusions and their impact on the application. This technical information gives an overview on the topics involved in the selection of the right specification for bubbles and inclusions.

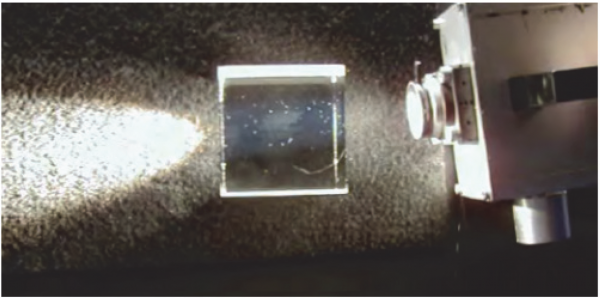

The inclusion quality will be assessed by visual inspection. To visualize the bubbles and inclusions, the following measurement setup is used in general. The glass is placed on a black background and illuminated from the side. The glass is viewed from above by looking through it toward the black background. The bubbles and inclusions become visible as bright spots. This arrangement is very sensitive for the quantification of bubbles and inclusions. To determine the sizes, either comparison standards or microscopes are used. The evaluation includes all bubbles and inclusions with dimensions ≥0.03 mm.

The bubble content is expressed by the total cross section in mm2 in a glass volume of 100 ccm, calculated from the sum of the detected cross sections of bubbles. Additionally the maximum allowable quantity per 100 ccm is defined. The evaluation considers all bubbles and inclusions ≥0.03 mm.

Inclusions in glass, such as stones or crystals, are treated as bubbles that have the same cross section. Typical maximum allowable total cross sections range from 0.03 to 0.006 mm2 per 100 ccm. The maximum quantity ranges from 10 per 100 ccm down to 2 per 100 ccm (bubbles larger than 0.3 mm).